09.07.21

Power Products International were tasked to provide a highly efficient fan cooled heatsink to cool a customer’s power module producing 1kW of heat dissipation. With an inlet ambient temperature of up to 50°C and a maximum allowable heatsink temperature rise of 20°C this meant a target heatsink thermal resistance of 0.02 K/W. Such a low thermal resistance therefore rules out the use of standard extrusions.

With the size of the single heat source being 305 x 170 mm this gave an initial indication of the size requirements of the heatsink. We always work to optimise the size and performance in order not to add unnecessary costs, etc. For example, increasing the length also increases pressure drop and ultimately reduces the amount of airflow from the fans. Unless the heat sources can be spread further apart over a larger heatsink surface, then it is often detrimental to a fan cooled heatsink.

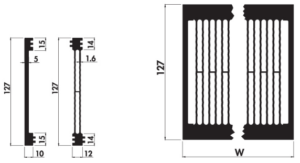

The starting point for the design would be to look at our range of High Performance Extrusions, these are aimed at use with fans and have a fairly high ratio of fins. The width of these heatsinks can be customised as they are mechanically assembled using multiple pieces of the small extrusion profiles, for example:

Combining the heatsink with the correct fan choice is also very important, Power Products International can simulate the performance of the heatsink at varied amounts of airflow and plot the pressure drop figures against the fan manufacturer’s performance curve. By doing this we can see the crossover point of the system impedance and therefore determine the operating amount of airflow from the fans.

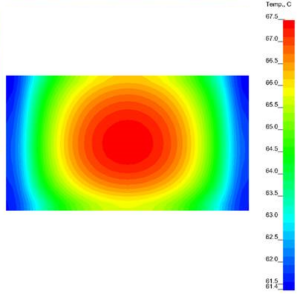

After choosing some appropriate fans for the heatsink and obtaining the amount of airflow, this gave simulation results of a maximum heatsink temperature of 67.5°C and an average of 65.1°C across the surface (ambient at 50°C):

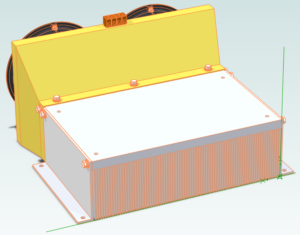

Although this fan cooled heatsink met the requirements, the customer was keen to see if the system could be improved even further. This meant looking at our Profilmecc heatsink type which is the most versatile and highest performing range. Dimensions such as length, width, base thickness, fin height, fin thickness and the distance between the fins can all be customised. The fins are mechanically inserted into the baseplate using a patented technology so there is no need for any bonding materials which add thermal impedance. Also, aluminium grades with higher thermal conductivity can be used or even copper if necessary.

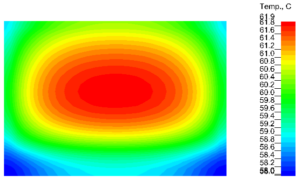

After optimising the design using the Profilmecc heatsink technology and appropriate fans this gave a performance of a maximum heatsink temperature of 61.9°C and an average of 60.5°C across the surface (ambient at 50°C):

The customer decided that the increase in performance outweighed the slight increase in cost for this system and Power Products International therefore designed, built and supplied the fan cooled heatsinks.

Contact us for more information:

+44(0)1732 866424