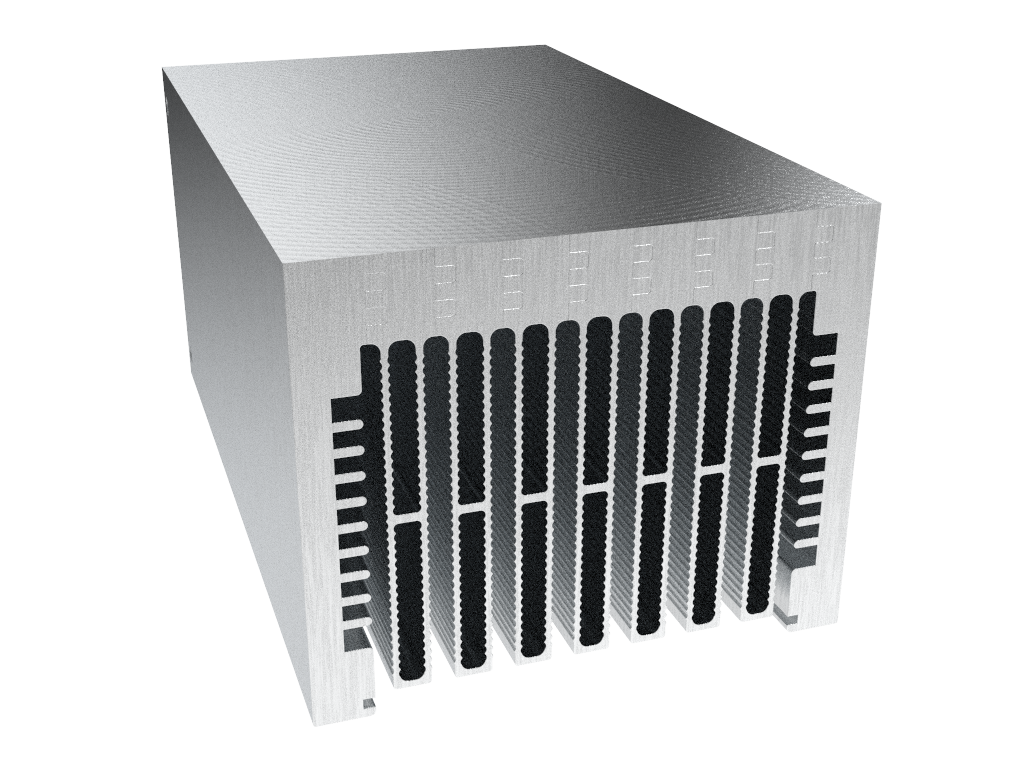

Power Products International’s high performance versatile heat sink systems are created by assembling the single fins mechanically together. These offer high dimensional flexibility together with the robust mechanical characteristics of extruded heatsinks.

These heat sinks are designed for use in high electric power systems using forced convection. The assembly types are categorised by width and height of the single fin which can be determined from the product code, as shown below in increasing order of size. e.g. PA8 40 = Fin 8mm wide x 40mm high

No downloads match those filters. Please try a different set of filters.

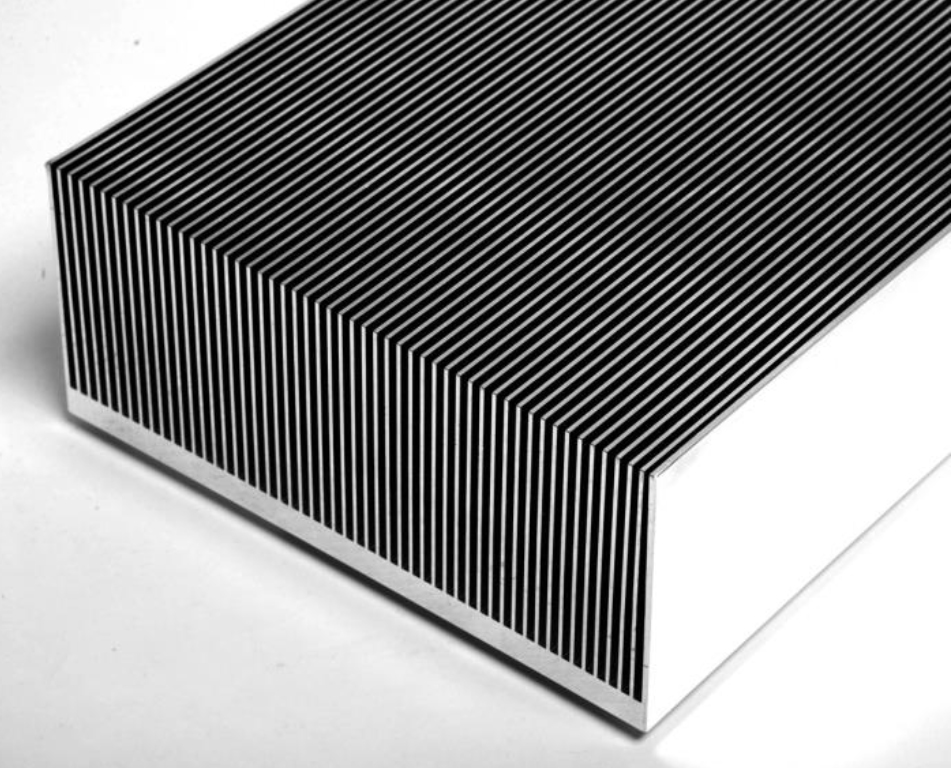

The Profilmecc and Profilmecc Plus range of high efficiency aluminium heatsinks from MeccAl completely changes current thinking on heatsink design, dimensional characteristics and performance.

With an aspect ratio of up to 75:1 for Profilmecc and 43:1 for Profilmecc Plus these heatsinks are of a monolithic structure that allows the engineer to design a completely customised solution from a standard base product. As with all aluminium heatsinks full machining, drilling and surface finishes are available.

When compared to the most efficient heatsinks from MeccAls’ competitors the factory reports that Profilmecc and ProfilmeccPlus will exhibit a decrease in thermal resistance of between 7% and 10%.

The best way to reach Power Products International Ltd is to fill out our contact form